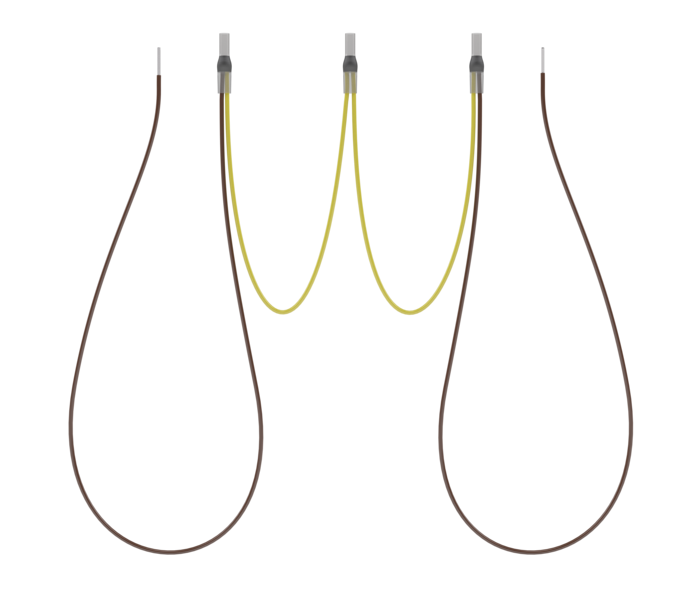

KRIWAN temperature sensors for winding installation are used to protect electrical machines against thermal overload. The constructive design achieves short thermal response times and simple installation characteristics. KRIWAN manufactures the PTC thermistors fully automatically with integrated test steps that ensure high and consistent quality.

KRIWAN offers a very wide range of different designs for winding sensors. We will be happy to advise you and together find the right winding sensor for your application.

100% testing - every sensor is tested

Further tests

Reliable protection against thermal overload and overheating

As specialists in the field, we offer cutting-edge technology to monitor temperatures in windings precisely and reliably. Our unique approach combines advanced PTC sensor technology with customized precision to exceed your requirements for winding temperature measurements.

PTC temperature sensors according to standard DIN VDE V 0898-1-401 (formerly DIN 44081 and DIN 44082) are used to protect electrical machines against thermal overload. An R/T characteristic, steeper than specified in DIN, characterizes KRIWAN thermistors. A range of types from 60 to 180 °C is available. PTC temperature sensors with different nominal switch-off temperatures can also be connected in series. This makes it possible to make optimum use of machine and winding parts with different limit temperatures and to protect them cost-effectively.

The PTC sensor on our page stands out for its outstanding sensitivity and accuracy, enabling the early detection of temperature changes in windings. Whether in power generation, electronics manufacturing, or other applications, our PTC sensors not only provide precise measurements but also set new standards in terms of durability and reliability.

| Max. Operating voltage | 30V |

| Tolerance of ϑNAT | ± 5K |

| Cold resistor R25 | ≤ 100Ω for single ≤ 300Ω for triple |

| Thermal response time | ≤ 5s |

| Insulation test | 2,5kV |

| Permissible ambient temperature | -25…+180 °C |

| Core insulation | FEP and ETFE |

| Prüfgrundlagen | DIN 44081/44082, DIN VDE 089-1-401 |

| Approval | UL (up to and including NAT 150°C) |

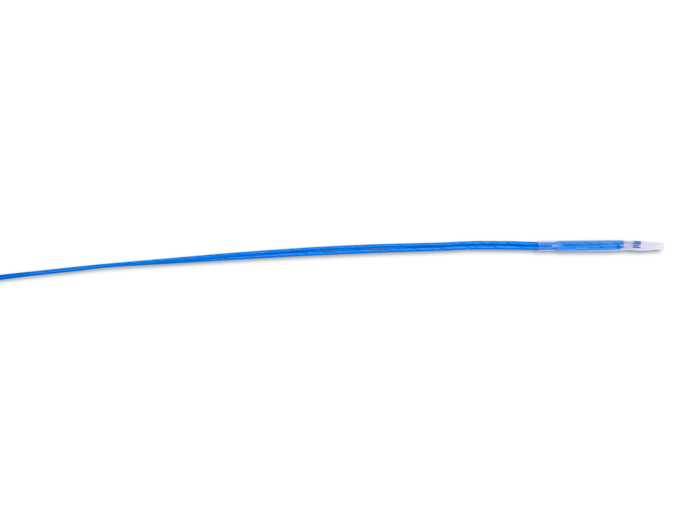

The sensors are used to measure temperature, mainly in refrigeration applications. High quality Pt100, Pt1000 temperature sensors reduce measurement errors and usually eliminate the need for adjustment. Technical features are determined by design and material. Particularly small dimensions guarantee a fast thermal response.

| Recommended measuring current | 1-3mA |

| Sensor resistance at 0°C | 100Ω ± 0,1Ω |

| Insulation test | 2,5kV |

| Permissible ambient temperature | -50…+200 °C |

| Core insulation | PTFE |

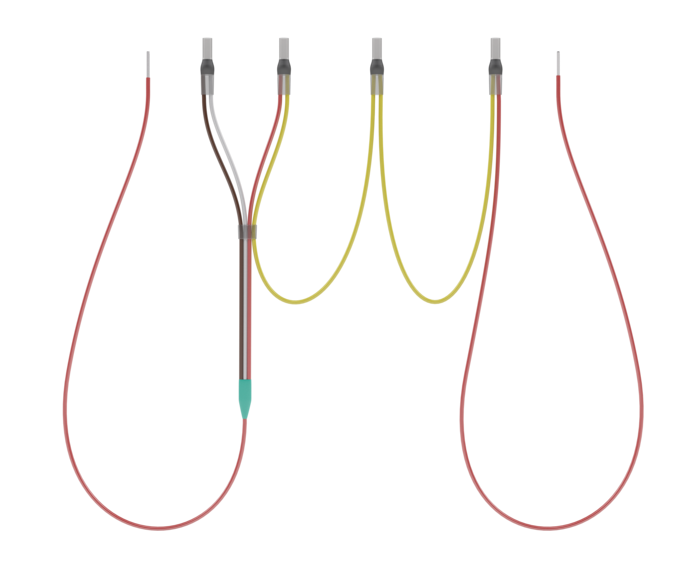

The PTC+ sensors developed by KRIWAN have a clear advantage over conventionally used PTC / NTC / PT100 / PT1000 sensors: the aim is to combine safe shutdown (PTC) and continuous temperature measurement (NTC / PT100/1000) in one sensor. This can safely and effectively prevent the motor from overheating, and at the same time the temperature can be measured with suitable evaluation electronics. It is thus possible, to initiate countermeasures in good time to prevent the system from being switched off. PTC+ sensors are available in the same designs as PTC sensors: with shrink tube insulation for winding installation, in sleeves or screw housings. PTC+ sensors are compatible with KRIWAN protection and diagnostic devices and can be used instead of conventional sensors. The picture shows an example of a sensor combination.

PTC+

| Thermal response time | ≤ 5s |

| Core insulation | FEP |

| Permissible ambient temperature | -25…+150 °C |

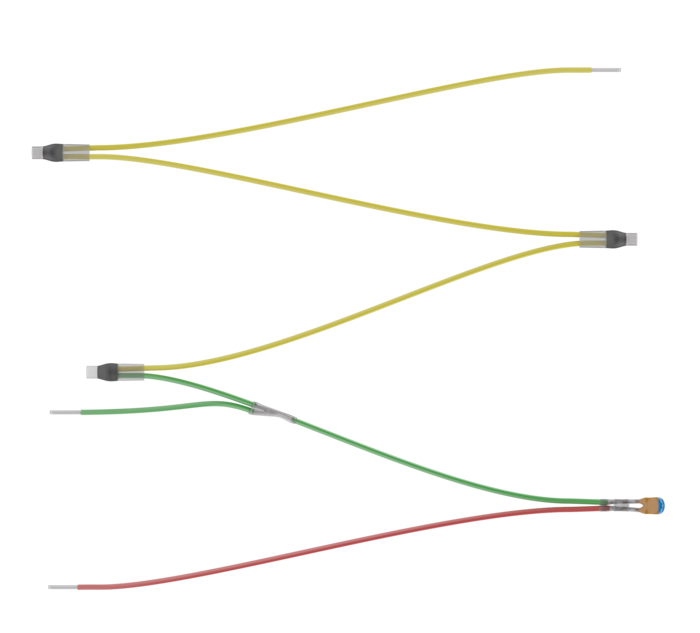

AMS sensors in combination with a KRIWAN diagnostic device enable a significantly earlier detection of a dangerous temperature rise in the electrical machine than previous PTC temperature sensors according to standard DIN VDE V 0898-1-401 (formerly DIN 44081 and DIN 44082)

Strong temperature rises are caused, for example, by blocking of the rotor and lead to high-temperature overflows in the application; these can be significantly reduced by using AMS sensors with KRIWAN diagnostic devices.

The AMS sensor can be connected together with another AMS sensor to ensure full functionality. The AMS sensor complies with the DIN VDE V 0898-1-401specification (according to characteristic curve) with regard to the temperature specifications for NAT, NAT +5k and NAT +15k. The characteristic curve before NAT is deliberately changed to allow significantly earlier diagnostics with connected KRIWAN diagnostic devices, this does not allow today's PTC sensors according to DIN VDE V 0898-1-401.

| Max. Operating voltage | 30V |

| Tolerance of ϑNAT | ± 5K |

| Cold resistor R25 | ≤ 400Ω |

| Thermal response time | ≤ 5s |

| Insulation test | 2,5kV |

| Permissible ambient temperature | -25…+150 °C |

| Core insulation | ETFE |

Installation locations of PTC sensors:

Together we will find the right winding sensor for your application!