The use of renewable energies is an environmentally friendly and sustainable alternative to energy generation. To make the best use of these energy sources, wind sensors are indispensable. Anemometers and wind direction sensors enable precise measurement of wind speed and direction to ensure the safe and efficient operation of wind power and photovoltaic systems.

With KRIWAN, you have a powerful partner for wind measurement devices at your side. Our anemometers and wind direction sensors are ideally suited for industrial applications due to their functionality and design. KRIWAN focuses on the highest quality in the manufacture and development of products. KRIWAN wind sensors are manufactured in Germany and are certified to the highest quality standards. KRIWAN is therefore the perfect partner when it comes to supplying innovative and reliable sensors that meet the requirements of the market.

Wind sensors are indispensable in the wind energy market, for example to optimize and ensure the performance of wind turbines. Wind measurement technology has made considerable progress in recent years. From LIDAR (Light Detection and Ranging) to sophisticated weather stations, modern instruments provide precise data collection that is essential for the development and operation of wind turbines. But what are the criteria for success when selecting wind sensors?

Precise and reliable measurement data even under extreme weather conditions such as hail, fog, freezing rain, etc.

Suitable for use in rough environments such as at sea or in mountainous regions, combined with a long service life to avoid costly replacements and repairs.

High quality, durability, precise measurement data combined with a reasonable price.

Operational reliability is ensured even under extreme weather conditions, and both climatic and mechanical influences can be withstood. Long-lasting usability is also of particular importance.

Latest Blogposts about wind measurement and wind measurement devices:

The accuracy of wind measurement directly influences the efficiency of wind turbines. With precise measurements, operators can not only select the best location for their turbines, but also optimize performance and reduce maintenance costs.

When selecting a wind measurement system for wind turbines, it is important to consider the specific requirements of the site. A carefully selected system not only ensures accurate measurements, but also contributes to the long-term profitability of the system.

There are various measurement methods in the wind energy sector for determining wind direction and wind speed. These can be assigned to the moving and non-moving wind sensors in terms of their modes of operation.

The measuring principle of mechanical wind sensors is a non-contact, magnetic scanning system based on a Hall sensor. This sensor is installed in the hull of the wind sensor and detects the magnetic field change caused by the moving magnet in the wind vane or in the cup star. As soon as this part of the sensor starts to move, the magnet placed inside it rotates with it and changes the magnetic field. The Hall sensor registers this change and derive the wind speed or wind direction from it.

There are two methods for measuring wind speed and direction with ultrasound wind sensors: time-of-flight measurement and the "acoustic resonance" measurement principle. Although these methods differ in their application, both use ultrasonic waves to measure wind speed and direction.

Time-of-flight measurement is a commonly used method for measuring wind speed and direction using ultrasound waves. In this method, a transmitter emits a short ultrasonic wave and then measures the time it takes for the wave to be received by the receiver. Since the speed of the wave is known, the measured time can be used to easily calculate the distance to the receiver so that the wind speed can be determined.

The "acoustic resonance" measurement principle is also very efficient in measuring wind speed and direction using ultrasonic waves. Here, the transmitter emits several short waves so that resonances can form on the reflected waves. These resonances reflect different frequency information based on the angle of the incoming wind and other factors such as temperature or air pressure. The sensor then measures this frequency information and uses it to calculate the wind speed and direction.

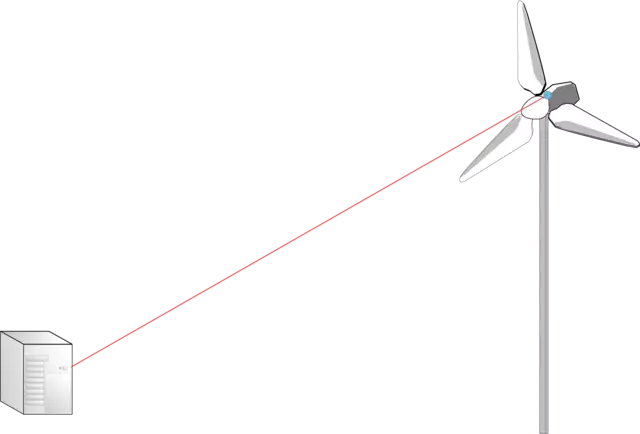

LiDAR wind sensors are optical measuring devices used in the wind energy industry to measure the speed and direction of air aerosols. The acronym LiDAR stands for "Light Detection And Ranging" and describes the measuring principle of the device.

A laser beam is emitted in front of the wind turbine and hits the air aerosols. These cause the laser beam to scatter, resulting in reflected beam components. With the Doppler effect, these components can be measured, which allows conclusions to be drawn about the speed and direction of the aerosols in the air.

Why KRIWAN wind sensors?

The design of the ICEfight sensors effectively prevents icing on the moving parts and ensuring reliable operation. The special feature of the KRIWAN solution: inside the cup star or vane there is a generously dimensioned heater, which is supplied with electrical energy from the fixed sensor part without contact and mechanical loss.

Disadvantage: Especially in the moving part there are numerous unheated areas.

Conclusion: Heating is insufficient to prevent operation of the sensor in ice and freezing rain

Advantage: The heat is generated where it is most needed

Conclusion: the successful commissioning was carried out together with industry experts and selected wind turbine manufacturers and showed: with the ICEfight, the turbine is resistant to freezing rain and any ice formation

On top performance: constant, accurate and stable data transmission over the wind turbine

KRIWAN wind sensors can also be used in various other areas. There is a suitable KRIWAN wind sensor for every environmental condition. They can be used in less demanding applications as well as in extreme conditions. We not only attach great importance to the quality of our products, but also offer first-class service. Our dedicated support team is always on hand to ensure that your wind measurement system runs smoothly.

KRIWAN at Olypmia Beijing 2022

KRIWAN ICEfight wind sensor in practical test

Extreme wind speeds, extreme heights and 9 lifts that will be built within the next 4 years: Doppelmayr is equipping the new ski resort for the Winter Olympics in Beijing - and KRIWAN is on board for the wind sensors!

About the story