2023-12-13 Products, Water and wastewater industry

Digitalization of pumps is becoming increasingly prevalent.

Pumps are durable assets and are typically used over many years, sometimes even decades. In new installations, digital enhancements are often already integrated. The pump can then transmit data indicating potential issues or that can be utilized for optimized control. But what about the extensive inventory of pumps already in the field? To move sensibly towards digitalization, these pumps also need an 'update' to continue using them for many more years.

What are the requirements for digital pumps?

To adapt existing pumps to the new digital era, certain conditions are crucial. Firstly, it's essential to capture as many vital parameters of the pump as possible. It's not sufficient to have data only on the motor, such as motor current. Fluid parameters like leakage or pressure are also crucial for pump analysis.

In addition to the parameters themselves, it's important that the retrofitting is straightforward. It should be possible to measure essential data without interfering with the pump itself, and the solution should be long-term stable. If batteries in sensors or electronics need regular replacement, monitoring multiple pumps securely over the long term becomes challenging.

Another crucial aspect is that IT interfaces may change in the coming years. Bluetooth or NFC are current technologies, but several years from now, this might be different. Therefore, digitalization should be designed to be future-proof and flexible. No one wants to invest again in the pump inventory in five or ten years.

Retrofit Pump Protection

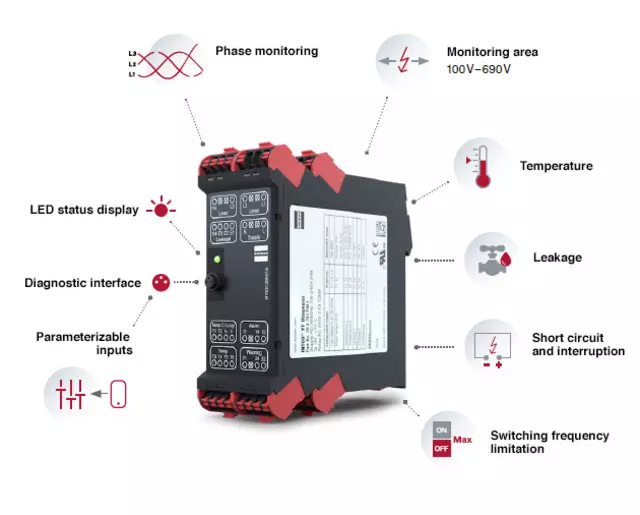

KRIWAN Industrie-Elektronik GmbH has been active in machine protection for 50 years, focusing on the protection of compressors and pumps. A new, fully digitalized protection relay for water and wastewater pumps not only enables the monitoring of new pumps but can also be easily retrofitted. The protection relay is mounted on the DIN rail in the control box or switchgear and stands out for its extreme flexibility in adapting to various situations. Starting with the inputs: three inputs are available for temperature sensors that can monitor motor temperature, bearing temperatures, or fluid temperatures, for example. Through an attachable Bluetooth or USB gateway, the INT69YF and the pump can be connected to a laptop or smartphone. Now, it is easy to configure in the field whether a sensor is a PTC, PT100, PT1000, or a bimetal switch. This allows the electronics to be adapted to various pumps and sensors installed in them. Shutdown temperatures and the behavior in case of a fault can be adjusted. It is also possible to set warning limits that indicate a critical situation before a fault occurs. This means that the sensors already used today can be easily and quickly connected to modern electronics with advanced digital interfaces.

In addition to temperature measurement, two inputs for leakage detection based on the conductivity measurement principle are also available. Moreover, any sensor with a 4-20 mA output can be connected. For example, a vibration or pressure sensor can be used here. These inputs can also be easily adjusted in their behavior and limits to the pump available on-site.

Finally, the electrical network with the three phases L1, L2, and L3 can also be monitored for under- or overvoltage, phase failure, or phase asymmetry.

All this data is digitized in the device and provided through a common interface. Gateways for Modbus RTU, Bluetooth, or USB can be attached to this interface. If other transmission methods become prevalent in the future, they can be retrofitted because the interface is not permanently built into the device. The protection relay itself is powered by mains voltage and is thus reliably operational, regardless of the limited lifespan of a battery. This is necessary because the INT69YF not only digitizes the pump by measuring data. The pump can also be effectively protected. In most cases, sensors for temperature, conductivity, or pressure are already built into the pump. They are usually used for pump protection. However, existing protection relays cannot communicate and are not ready for digitalization. Therefore, KRIWAN has taken the step to combine both tasks: a protection relay now integrates all essential functions of digitalization and can be easily retrofitted.

Concrete Steps for Retrofitting

How can such retrofitting of existing pumps be implemented? The following section describes key points on how a digitization project can be carried out concretely.

Define Project Objectives

Digitization of machines can be initiated for various reasons. It is crucial to clarify the objectives that need to be achieved beforehand. Sometimes, there's a common sentiment in companies and the media: "Let's just start and collect as much data as possible. We'll figure out exactly what to do with it later." While this approach may work in individual cases and be successful, in many instances, it leads to data dumps on servers and hard drives that do not provide real economic or societal benefits. Therefore, in a digitization project, it's important to create a plan and set goals from the beginning. However, it may not be possible to define everything for many years in advance right now because technology and possibilities change quickly. The plan and goals should be regularly reviewed and adjusted to new developments. Such a 'living' plan is more dynamic than what is typically necessary and sensible in many traditional projects.

Possible Goals of Retrofitting Digitalization for Existing Pumps

Concrete Implementation of a Digitization Project

To lead a digitization project to success, several points need to be considered:

Literature

[1]: Ellwein, C.: Rethinking Security – Cybersecurity for Compressors, Pumps, and Fans; Refrigeration and Air Conditioning Technology; 11/2017; pp. 36 – 39

[2]: Neidhöfer, M.: Shield for the Component – Defending Against Cyber Attacks on Pumps and Compressors; cav; 01-2018; pp. 38 - 40"

Do you have further questions or comments about the blog post? Please contact us!