The level switches BASIC from KRIWAN are the optimal solution for reliable liquid monitoring in standard applications. With a robust design and proven technology, they ensure consistent performance in a wide range of environments. Whether in process control or building automation, the BASIC models offer an economical solution without compromising on quality.

The BASIC IceFight level monitor is used in low temperatures and are specially designed to protect against icing.

With simple installation and versatile application options, they are the first choice for applications where a stable, proven product is required.

Areas of application

Wide range of applications for level switches BASIC

Efficient cooling requires precise monitoring of fluid levels in order to avoid loss of performance or damage due to insufficient lubrication. The BASIC sensors reliably monitor the minimum fluid level in cooling systems and thus ensure smooth operation.

In heating and ventilation systems, liquid level sensors play a crucial role in detecting a lack of water at an early stage and preventing damage to pumps or heat exchangers. The BASIC series offers a stable and cost-effective solution for these applications.

The level switches BASIC ensure precise monitoring of the oil level and thus prevent both low and excessive levels. This not only ensures smooth operation, but also protects the compressor components from damage caused by insufficient lubrication.

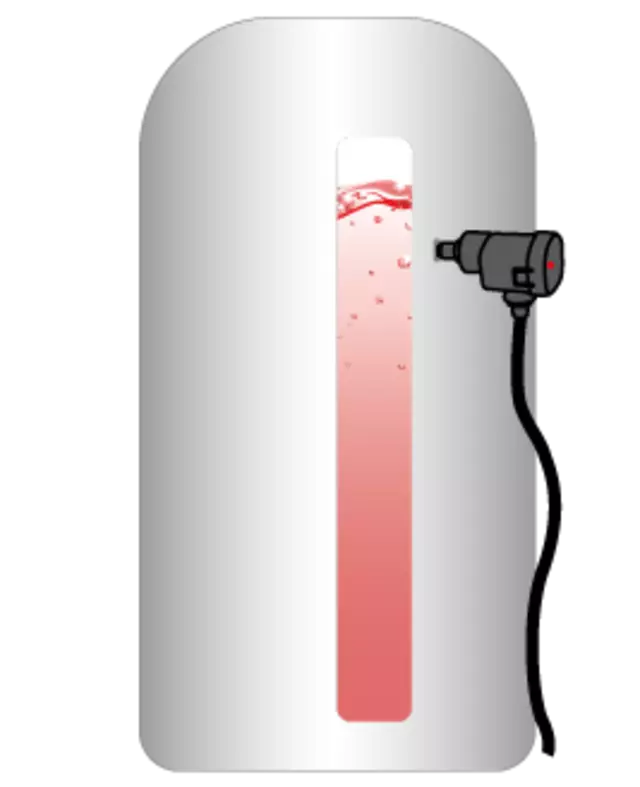

Moisture from the warm ambient air always condenses at the coldest point. If this is the refrigerant collector, this can lead to icing between the glass cone and the evaluation unit. The BASIC IceFight product variant was specially developed for this purpose. It is optimised for use on CO₂ refrigerant collectors and is resistant to icing of the optical measuring principle.

KRIWAN offers you a variety of optical level switches with different technical specifications. In the following table, you will find a small selection of our level switch.

Contact our specialists and we will find the right product together with you!

| Designation: | INT275 L | INT276 LC | INT276 GR | INT276 LN | INT277 LA | INT278 LCA | INT279 LN | INT279 LX |

| Permitted media temperature | max. +80 °C | max. +80 °C | max. +100 °C | max. +100 °C | max. +100 °C | max. +100 °C | max. +100 °C | max. +100 °C |

| Function | min | min | max | min | min | min | min | max |

| Start-up bridging | no | no | no | no | 30 sec. | 90 sek. | 30 sec. | no | no |

| Switching delay | 3 sec. | 3 sec. | 3 sec. | 3 sec. | 3 sec. | 3 sec. | 3 sec. | 3 sec. |

| Interlocked shutdown | no | no | no | no | yes | yes | no | no |

| Run detection | no | no | no | no | yes | yes | no | no |

| Alarm contact | Closer | Closer | Changeover | Changeover | Changeover | Changeover | Changeover | Changeover |

| Connection cable length | 1 m | 1 m | 1 m | 2 m | 1 m | 1 m, 3 m | 10 m | 10 m |

| Certification | UL | UL | UL | UL | UL | UL | no | no |

| Power Supply | AC 50/60 Hz 230V AC 50/60 Hz 115V AC/DC 50/60 Hz 24V | AC 50/60 Hz 230V AC 50/60 Hz 115V | AC 50/60 Hz 230V AC/DC 50/60 Hz 24V | AC 50/60 Hz 230V | AC 50/60 Hz 230V | AC 50/60 Hz 230V AC 50/60 Hz 115V | AC/DC 50/60 Hz 24V | AC/DC 50/60 Hz 24V |

| Designation: | INT276 ICN | INT276 ICX |

| Permitted media temperature | max. +120°C (<16.000h) max. +100°C | max. +120°C (<16.000h) max. +100°C |

| Function | min | max |

| Start-up bridging | no | |

| Switching delay | 3 sec. | |

| Interlocked switch-off | no | |

| Run detection | no | |

| Alarm contact | Changeover | |

| Connecting cable length | 1m, 2m, 5m, 10m | 1m, 5m, 10m |

| Certification | no | no |

| Power Supply | AC50/60 Hz 230V AC/DC 50/60 Hz 24V | AC50/60 Hz 230V AC/DC 50/60 Hz 24V |

Are you looking for product data sheets for our level switches? Then use our product search. Simply enter the article number or article name in the search field and select the ‘Products’ tab.

Low fluid levels in systems such as refrigerant compressors, pump systems or oil tanks can cause significant problems, from insufficient lubrication to serious damage to machine components. Especially in refrigeration systems, a stable oil circuit is crucial to avoid compressor failures and costly repairs. In heating and cooling circuits, too low a level also leads to a loss of operating efficiency and increased energy consumption.

The level monitor BASIC and BASIC IceFight offer a reliable solution for monitoring minimum fill levels. With their robust design and proven technology, they precisely detect whether a critical point has been reached and trigger alarms or shutdowns in good time. Operators benefit from this simple but effective solution as unplanned downtime is avoided and maintenance costs are reduced. Examples of applications include

With the level switches BASIC and BASIC IceFight, you as the operator receive a cost-efficient and easy-to-integrate product that offers maximum safety and reliability in standard applications.

An excessive fluid level can also have serious consequences in many industrial applications. In refrigeration systems, for example, excess oil or refrigerant can flow back into the compressor and cause damage to the machine. An excessive level in tanks or containers can also lead to leaks, waste of material or even environmental pollution due to uncontrolled leakage of liquids.

The level monitor BASIC guarantee precise monitoring and reliable protection against excessive liquid levels. Thanks to their proven technology, they detect at an early stage when the critical maximum value is exceeded and enable a timely response, such as stopping filling or activating safety valves. Typical applications are:

Level switches BASIC and BASIC IceFight are the perfect choice for operators as they offer a robust, low-maintenance solution that can be seamlessly integrated into existing systems. With these sensors, high safety and efficiency standards can be guaranteed in standard applications.

Our level monitor categories for every application:

The level switches ADAPT stand for maximum flexibility and easy integration. Thanks to the innovative M12 plug-in connection, cables can be attached individually and as required. This solution offers enormous advantages, especially in large systems: Maintenance work can be carried out quickly and efficiently, as the cable can remain unchanged in the wiring harness. The level monitor ADAPT also makes it easy to replace the sensor without the need for an electrician. Perfect for applications where customisability and reliability count.

More product information, technical data and areas of application

The level switches ADAPT EXTENDED have been specially developed for demanding applications. With a temperature resistance of up to 160°C and encapsulated electronics, they are ideal for use in heat pumps and refrigerant compressors. The innovative design prevents icing and increases durability even under extreme conditions. The level monitor ADAPT EXTENDED is the first choice for systems that have to work with modern refrigerants and high temperature requirements.

More product information, technical data and areas of application

The level switches EX offer maximum safety in potentially explosive environments. With their specially certified design, they fulfil all requirements for use in areas such as chemical plants, refineries or other industries with potential explosion risks. The sensors in this series guarantee maximum reliability, durability and protection - even under the most demanding conditions. The level monitor EX is the ultimate solution for operators who do not want to take any risks.

More product information, technical data and areas of application