2022-12-08 Successstory, Company

Itself is a market leader

What does a development company from the Hohenlohe region in Germany do to avoid waiting times and high external costs when testing new developments? It creates its own modern testing environment, perfectly matched to the individual requirements.

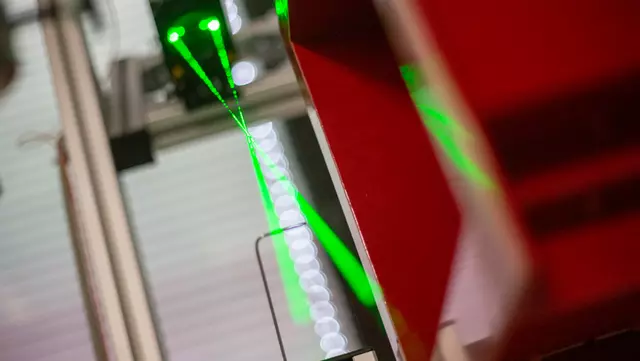

Some time ago, KRIWAN invested in a complex test center – and extended it a few years ago to include an additional wind tunnel. Here, air flow monitors and wind force sensors are put through their paces – quickly, reliably and in line with latest technical standards.

With a threatening roar, the wind tears past sensitive sensors. The wind speed measures 159 kilometers per hour – force 12 wind. Something usually expected on the North Sea coast or at the summit of Germany's Zugspitze mountain is being experienced in a small lab in Forchtenberg, Germany. Because this is where KRIWAN tests its new product developments under extreme conditions.

In 2017, for around € 140,000, a state-of-the-art flow lab was built, centered around the ›Göttingen-type‹ Westenberg wind tunnel. This system was developed back in 1908 and, since then, it is use has remained virtually unchanged.

Downstream of the 600mm long test section where the relevant test object is placed, air is drawn via a fan into a collector. This is routed through a duct and flows back in at the other end of the test section via a nozzle.

The "closed" system that is created has many advantages – and a high level of efficiency: No influences can affect the test section and adulterate the result.

"Thanks to our in-house flow lab, there is virtually nothing standing in the way of our developers' ideas – or our customers' requirements."

Diethard Sawallisch

Project Manager of Innovation & Development at KRIWAN Industrie-Elektronik

From storm to still

Depending on the requirements and test series, various wind forces can be simulated in the KRIWAN wind tunnel. These range from barely perceptible flows of just 0.1 meters per second all the way up to a wind speed of 160 km/h, which corresponds to a powerful force 12 hurricane.

The wind force can also be precisely adjusted and maintained even over long periods – a huge advantage compared with testing in a natural environment, where the flow force varies continuously and repeatedly slows or picks up. And the wind direction in the lab also remains constant, as does the temperature and air pressure, which, naturally, can also be defined.

Measurements can be carried out under internationally applicable normal conditions (a temperature of 20° Celsius and an air pressure of 1013 hectopascals), so they can be reproduced anywhere in the world.

Testing from the start

For the "Innovation & Development" department, the in-house flow lab opens unique possibilities. New products can now be tested repeatedly during the first development phase under real conditions.

Previously, it was necessary to rely on computer simulations or use external labs, involving additional development costs. And often long waiting times.

Today, KRIWAN developers benefit not only from low costs, but also from a considerable time saving compared with their competitors.

An important criterion for success in a world with an ever-increasing rate of development.