2024-09-27 Products, HVAC/R

Heating offi ce, commercial, or industrial buildings plays an extremely important role in achieving our climate goals. This is because a large portion of our CO2 emissions come from traditional heating systems. At the same time, the topic of „heat“ presents enormous savings potential.

In terms of environmental friendliness, long-term cost savings, and adaptation to future energy policies, heat pumps are becoming increasingly attractive. However, what happens when such a significant investment, especially for industrial purposes, breaks down? There are numerous reasons for failures: an overheated motor, insufficient coolant levels, or an untested lubrication system. The damage from such failures is often very costly.

Additionally, there are further challenges associated with the acquisition and use of heat pumps. The F-Gas regulation is phasing out many refrigerants due to their environmental impact. This presents heat pump manufacturers with the challenge of finding and implementing alternative refrigerants that are both efficient and environmentally friendly. Typically, manufacturers resort to flammable refrigerants, which in turn require explosion-proof electronics.

To address these challenges, KRIWAN offers suitable solutions to protect heat pumps, ensuring long-term efficiency and reliability. The system is stopped before it becomes costly.

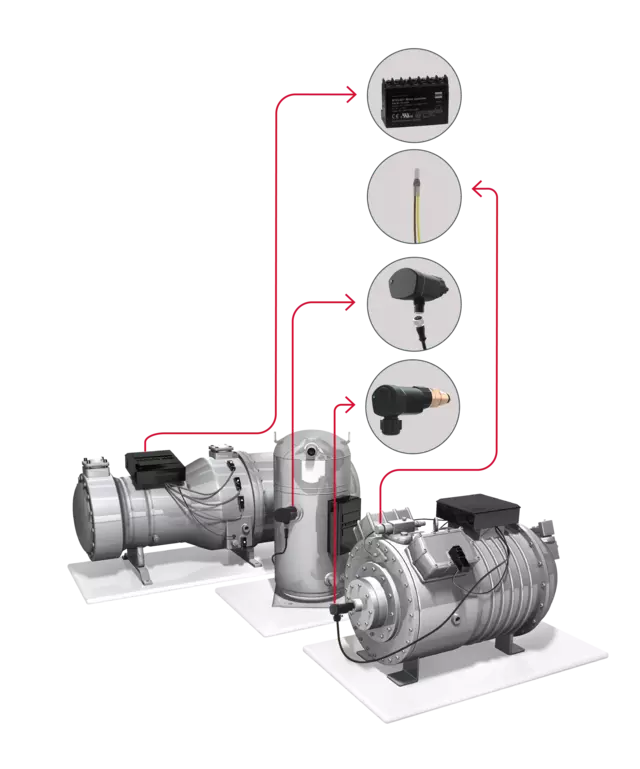

The INT69 motor protection, based on PTC sensors, is one of the most effective and reliable measures against thermal overload of electrical machines. Its compact design allows it to be installed both directly in the heat pump and in the control panel. It is also compatible with flammable refrigerants.

The optical level monitoring INT275-INT279 is used for non-contact singlepoint measurement of liquid levels. Thanks to the combination of evaluation unit and screw-in part, the devices can be exchanged or installed without opening the heat circuit. The KRIWAN level sensors with plug connections enable easy installation, operate at temperatures up to 160 °C, and are well-suited for A2L and A3 refrigerants.

The DELTA-P II is a reliable stand-alone solution for monitoring the lubrication system of reciprocating compressors. The KRIWAN differential pressure monitoring allows precise and non-contact measurement of differential pressures in oil pumps, even at medium temperatures up to 120 °C. An integrated LED provides immediate visual indication of whether the differentialpressure is within the safe range, too low, or if there is an internal fault.

Advantages

The advantages of KRIWAN protection systems for heat pumps are manifold.

Do you have further questions or comments about the blog post? Please contact us!