The future of power supply undoubtedly lies in renewable energies, particularly in modern and efficient wind power. KRIWAN makes it possible with innovative solutions revolving around the topic of wind power.

Wind turbines are especially effective in regions where the conditions are harsh. Strong winds can not only contribute to an increase in energy production but also pose a threat to the wind turbine. Through comprehensive wind monitoring, combined with intelligent software, KRIWAN provides effective protection for both offshore and onshore installations, regardless of the weather conditions at the respective location.

Simultaneously, KRIWAN solutions can be utilized to enhance the efficiency of a wind turbine: initiating wind turbines only when the wind is strong enough and economically viable, as well as aligning the system perfectly with the wind. The alignment of a wind turbine directly determines how efficiently it can convert the kinetic energy of the wind into electrical energy. Precise alignment ensures that the rotor blades are optimally exposed to the wind, leading to maximum energy generation.

KRIWAN sensors

So you don't miss anything when it comes wind power

The reliable collection of wind data forms the crucial foundation for condition monitoring and the efficient operation of modern wind turbines, whether they are onshore or offshore, whether individual units or part of a large wind farm. The choice of location plays a pivotal role in the alignment of wind turbines. A meticulous analysis of wind directions and speeds is essential to align the turbines optimally and maximize energy production. In this process, KRIWAN's solutions capture not only wind speed and direction but also the temperature of various components of the wind turbine or the oil circuits.

The result: reduced maintenance efforts, efficient operation, and decreasing costs.

Pointing the way: Our wind direction sensors provide reliable data in any weather.

Strong performance in all conditions: Our wind sensors deliver reliable operating values for the turbine.

Keeping a consistent temperature: Our temperature sensors indicate when critical temperature ranges are reached.

A COOL RESPONSE!

ICEfight® applications

Our experts conduct detailed site analyses to identify the best alignment options. Through advanced planning techniques, we ensure that your wind turbines are optimally aligned under the given conditions. Read a successful implementation example here.

learn moreKRIWAN connectivity

Various data, one smart system

The alignment of wind turbines is a key factor in their efficiency. With our experience and state-of-the-art technology, we ensure that your installations are optimally positioned to make a sustainable contribution to energy generation.

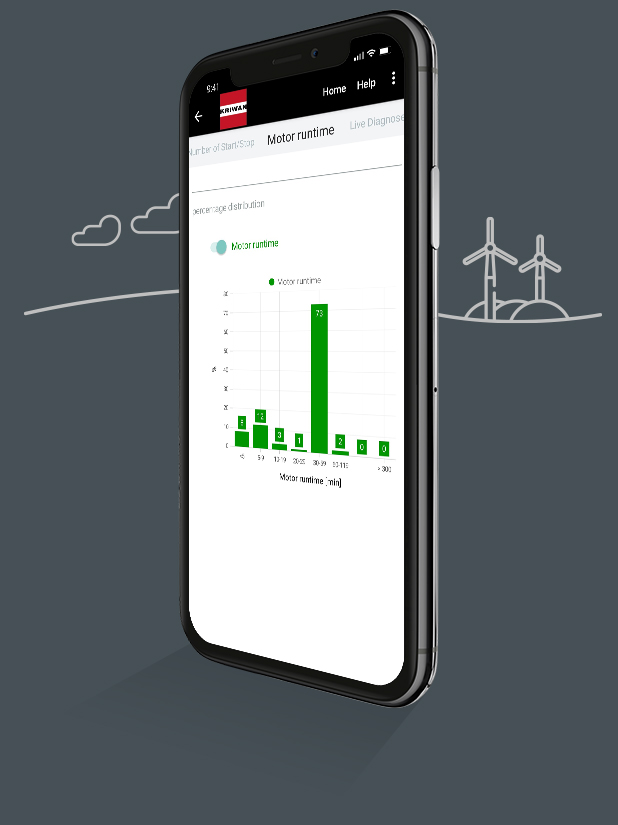

Fundamentally, the system KRIWAN uses to ensure maximum reliability is simple: Highly sensitive sensors permanently measure wind power, wind direction and other functions such as the temperature of the motor. The data captured in this way is transferred in analog or digital form via a smart condition monitoring system for real-time analysis and evaluation.

If the system identifies that defined safety limits have been exceeded, the turbine is shut down and, depending on the situation, the blades go into carefree mode or are rotated out of the wind, braked and locked in place.

This automatically prevents damage to the wind turbine.

Naturally, it is not only for safety purposes that the KRIWAN system responds to changing conditions. For efficiency also, accurate measurement readings are critical to ensure that the turbine starts up in good time when wind speeds are right and is continuously aligned to the wind to achieve optimum effect.

For more effective wind turbine operation.

Features of our sensors (wind direction and anemometer)

ICEfight – innovative wind sensors