Mit KRIWAN die Zukunft gestalten

Internet of Things oder Industrie 4.0: Die Themen Digitalisierung und Vernetzung sind längst in alle Bereiche unseres Lebens eingedrungen und nehmen Tag für Tag an Bedeutung zu. Der schnelle, unkomplizierte Austausch von Daten, intuitive Steuerung und einfach nutzbares Monitoring bilden dabei die Grundlage aller Lösungen und Anwendungen.

KRIWAN erhebt nicht nur wichtige Daten im Herzen von Maschinen und Anlagen, durch intelligente Connectivity-Lösungen stellt sie diese auch bereit, damit Betreiber die so gebündelten Informationen einfach auswerten und vorausschauend reagieren können.

Mit zukunftsweisender Hardware und Software, die sich einfach in die Anlagenumgebung intergrieren lassen.

Was wäre, wenn Sensorik und Schutzgeräte in Ihren Scroll-Kompressoren integriert werden könnten – und Connectivity möglich wird?

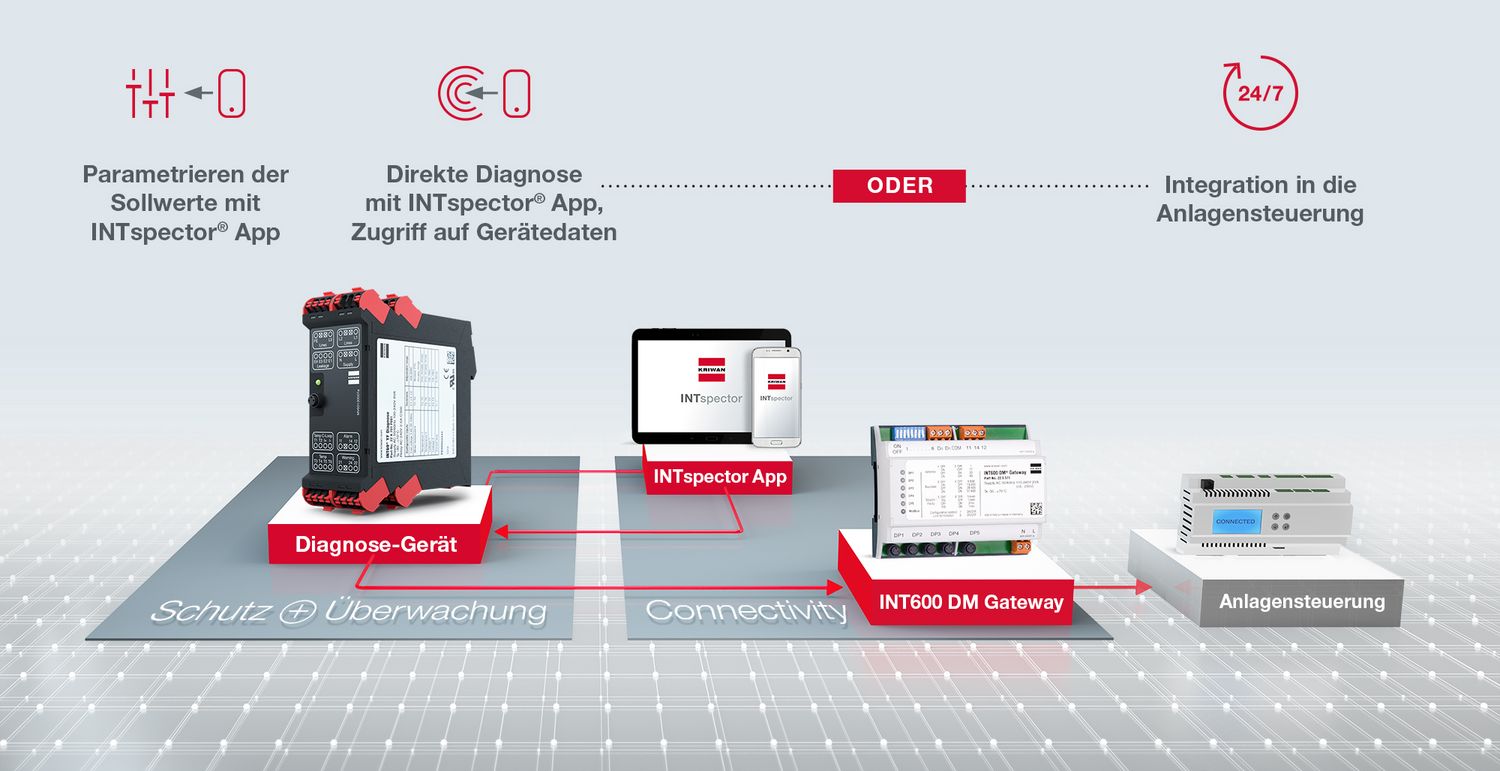

Smarte Lösung: Die Diagnose-Varianten unserer Schutzkompenten speichern Informationen und verfügen über notwendige Schnittstellen.

Optimal vernetzt: Die KRIWAN Modbus Gateways stellen sicher, dass alle Komponenten und Systeme Daten zuverlässig austauschen.

Mit der INTspector App können Sensoren und Schutzgeräte noch einfacher ausgelesen werden – am PC und auf dem Smartphone.

KRIWAN Connectivity

Das KRIWAN Diagnose-System im Überblick

KRIWAN bietet eine Komplettlösung zur Vernetzung der Diagnose-Geräte mit Ihrer Anlage. Das intelligente KRIWAN Diagnose-System ist leicht zu implementieren, flexibel und skalierbar und ermöglicht Ihnen Condition Monitoring: für Ihren verlässlichen und effizienten Anlagenbetrieb.

Als echter Systemanbieter entwickelt KRIWAN komplexe Lösungen aus einer Hand, optimal auf die jeweilige Anforderung abgestimmt. Dabei verfügen alle Komponenten über integrierte Schnittstellen, die frei parametrierbar sind und so intelligent und sicher vernetzt werden können.

Das Ergebnis: maximale Konnektivität, maximale Transparenz und maximale Betriebssicherheit – bei minimalem Aufwand und niedrigen Kosten.

Immer richtig verbunden

Als echter Systemanbieter entwickelt KRIWAN komplexe Lösungen aus einer Hand, optimal auf die jeweilige Anforderung, die Prozesse und die bestehende Umgebung abgestimmt. Dabei verfügen alle Komponenten über integrierte Schnittstellen, die frei parametrierbar sind und so intelligent und sicher vernetzt, werden können.

Das Ergebnis: maximale Konnektivität, maximale Transparenz und maximale Betriebssicherheit – bei minimalem Aufwand und niedrigen Kosten.

Cybersecurity by KRIWAN

Die zunehmende Digitalisierung und Vernetzung bietet jede Menge Vorteile. Aber sie birgt natürlich auch Risiken. Denn Cyberangriffe und der unerlaubte Zugriff auf Daten und Anlagen können erhebliche Folgen haben. Rechenzentren benötigen eine permanente Kühlung, Pumpen in Wasserwerken garantieren die Versorgung ganzer Städte, ebenso wie Windkraftanlagen.

Deshalb geht KRIWAN auch hier auf Nummer sicher: Schutzrelais können nur vor Ort umprogrammiert werden, was einen Systemeingriff über das Internet nahezu unmöglich macht.

Außerdem sind sie, ebenso wie Gateways und Sensoren, jeweils mit zwei Mikroprozessoren bestückt, von denen nur einer mit dem Internet verbunden ist. Wird dieser angegriffen, werden Veränderungen durch konstanten Vergleich mit den Messergebnissen des Offline-Prozessors in Echtzeit erkannt und Schutzmaßnahmen eingeleitet.

Natürlich entsprechen auch alle Wege der Datenübertragung oder genutzte Clouds höchsten Sicherheitsstandards.

So bietet KRIWAN Sicherheit hoch zwei.